What Is a Lean Transformation Roadmap?

- Michelle M

- Jul 10, 2025

- 6 min read

Businesses are turning to Lean transformation as a way to evolve, but Lean transformation is not a simple initiative or a single project it is a fundamental shift in mindset, operations, and culture. And like any significant change, it requires a strategic plan to map and guide the journey. That strategic plan is known as a Lean Transformation Roadmap.

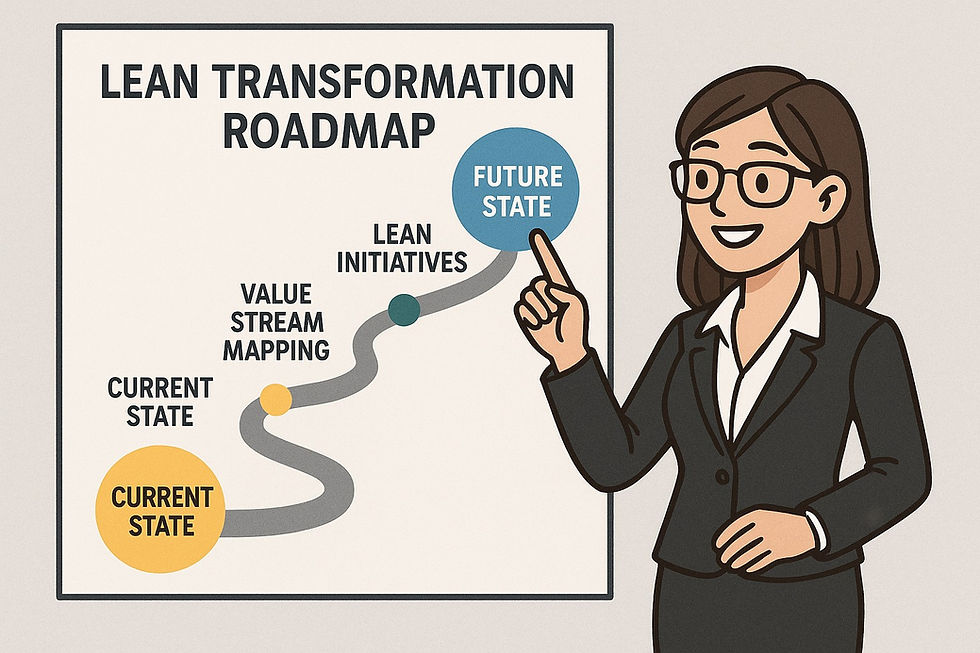

A Lean transformation roadmap is a structured, step-by-step guide that organizations use to transition from traditional ways of working to Lean-thinking principles that prioritize value, eliminate waste, and empower people at every level. This roadmap doesn't just lay out processes; it defines purpose, shapes behaviors, and aligns leadership around long-term change.

Whether you're a startup wanting to scale responsibly, a manufacturer aiming to reduce lead times, or an enterprise seeking enterprise-wide agility, a Lean transformation roadmap can be the compass you need to steer your efforts. This blog will explore what a Lean transformation roadmap is, why it's important, what it includes, and how to build one for real results.

Understanding Lean Thinking

To grasp the essence of a Lean transformation roadmap, we must first understand Lean itself. Lean is a philosophy and methodology rooted in the Toyota Production System (TPS), designed to deliver more value to customers using fewer resources by continuously identifying and eliminating waste.

At its core, Lean is about:

Maximizing value for the customer

Minimizing waste in all forms (overproduction, waiting, defects, unnecessary motion, inventory, overprocessing, underutilized talent)

Continuous improvement through small, incremental changes

Empowering teams to take ownership of their work

Creating flow by reducing interruptions and bottlenecks

Lean has evolved beyond manufacturing into sectors like healthcare, software, finance, education, and government. But while tools like Kanban, 5S, and value stream mapping are helpful, true transformation is cultural and that's where a roadmap is crucial.

What Is a Lean Transformation Roadmap?

A Lean Transformation Roadmap is a strategic plan that outlines the stages, priorities, actions, and milestones needed to adopt and sustain Lean principles across an organization. It serves as a visual and tactical reference that helps leaders and teams navigate the complexities of change, from mindset shifts to operational redesigns.

Rather than imposing change top-down, a good Lean roadmap is collaborative, evolving, and grounded in continuous learning. It balances long-term vision with short-term wins and ensures that Lean is not just a department-specific initiative but an enterprise-wide culture.

Why You Need a Lean Transformation Roadmap

Embarking on Lean transformation without a roadmap is like navigating an unknown city without a map or GPS. Here’s why a roadmap is vital:

1. Alignment

It aligns leadership, departments, and teams on the goals and sequence of transformation activities.

2. Clarity

It provides a shared understanding of where the organization is, where it wants to go, and how to get there.

3. Focus

It prevents Lean from becoming a scattered set of disconnected tools and ensures focus on value creation.

4. Engagement

Employees feel more secure and involved when they see a clear plan for transformation and understand their role in it.

5. Measurement

It establishes metrics to track progress, celebrate wins, and adjust course as needed.

Key Components of a Lean Transformation Roadmap

While the specifics of a roadmap will vary based on organizational size, industry, and maturity, several core components are common across successful transformations.

1. Current State Assessment

Start by evaluating where you are today. This includes:

Understanding current processes and workflows

Identifying sources of waste

Assessing organizational culture and leadership alignment

Mapping customer value streams

This baseline helps define the gap between the current and desired state.

2. Vision and Purpose

Define a compelling Lean vision that connects with your organizational mission. This should answer:

What are we trying to achieve with Lean?

How does this align with customer needs?

What will success look like in 1, 3, and 5 years?

A clear vision becomes the North Star of the transformation.

3. Leadership Commitment and Training

Lean transformation fails without leadership support. Roadmaps must include:

Leadership development and Lean training

Leadership participation in Gemba walks (on-the-ground observations)

Regular reviews and alignment meetings

Leaders must model Lean behaviors, not just fund them.

4. Lean Governance Model

Define how decisions will be made, who owns what, and how progress will be monitored. This may involve:

Lean transformation office (LTO) or PMO

Agile coaches or Lean experts

Cross-functional working groups

Clear roles and decision rights prevent transformation from stalling.

5. Pilot Projects and Quick Wins

Start small. Identify 1–3 value streams or departments where you can run pilots. Choose areas with:

High visibility

Measurable outcomes

Willing participants

Quick wins build momentum and serve as proof of concept.

6. Culture and Mindset Shift

Cultural transformation is at the heart of Lean. Your roadmap should include:

Workshops on Lean mindset and behaviors

Empowerment programs for frontline employees

Communication plans that reinforce the “why” behind change

Changing habits takes time and consistency.

7. Tool Adoption

Introduce Lean tools based on real needs, not trends. Examples include:

Value stream mapping

5 Whys and root cause analysis

A3 problem solving

Visual management boards

Daily stand-ups (huddles)

Continuous flow and pull systems

Tools should support goals, not become the goal themselves.

8. Metrics and KPIs

How will you measure progress? KPIs may include:

Lead time

Cycle time

Process efficiency

Customer satisfaction

Employee engagement

Cost savings

Define baseline metrics and track them over time.

9. Scaling and Integration

Once pilot areas succeed, expand the transformation to other departments or business units. This involves:

Adapting practices to different contexts

Sharing lessons learned

Avoiding “copy-paste” solutions

Integration with HR, finance, and IT is often required to embed Lean into core operations.

10. Sustainability and Continuous Improvement

Lean is not a destination but a journey. Build a cadence of improvement with:

Kaizen events

Team retrospectives

Leadership reviews

Annual strategy deployment (Hoshin Kanri)

Embed improvement into your DNA so Lean doesn’t fade when leadership changes.

Phases of a Lean Transformation Roadmap

Although each transformation is unique, most roadmaps follow similar phases:

Phase 1: Discover and Align

Conduct current state assessments

Identify gaps and opportunities

Engage leadership

Define the Lean vision

Set transformation goals

Phase 2: Launch and Educate

Establish governance and teams

Train leaders and early adopters

Run initial workshops

Begin communication campaigns

Phase 3: Pilot and Prove

Select 1–2 pilot areas

Map value streams

Eliminate waste

Measure and publicize results

Phase 4: Expand and Scale

Roll out successful practices to other areas

Adapt tools to local contexts

Align with digital transformation initiatives

Share internal success stories

Phase 5: Embed and Sustain

Build improvement into performance management

Train new hires in Lean thinking

Maintain visual controls and metrics

Institutionalize retrospectives and kaizen

Common Pitfalls and How to Avoid Them

Many organizations fail in their Lean transformation due to avoidable missteps. Be wary of:

1. Tool-Only Mentality

Adopting tools without changing behaviors results in shallow transformation. Focus on principles first.

2. Top-Down Imposition

Lean can’t be mandated. Involve teams, respect their insights, and co-create solutions.

3. Lack of Leadership Follow-Through

Leaders must participate and model Lean practices consistently.

4. Ignoring Culture

Culture eats strategy for breakfast. If you don’t address mindset, you’ll never achieve sustainable change.

5. No Time for Improvement

If people are too busy to improve, nothing will improve. Allocate time for reflection and learning.

Real-World Examples of Lean Roadmap Outcomes

Organizations that implement Lean transformation roadmaps successfully report impressive results:

Hospitals have reduced patient wait times by 50% and improved care quality

Manufacturers have improved delivery times by 30–70% while reducing costs

Software teams have cut defect rates in half and doubled release frequency

Government agencies have increased public satisfaction and reduced red tape

Retail companies have streamlined inventory management and improved in-store experience

What these examples share is not just better metrics but stronger cultures of learning, empowerment, and value delivery.

Conclusion

A Lean Transformation Roadmap is more than a schedule or checklist. It is the compass that guides your organization toward becoming more efficient, responsive, and purpose-driven. It connects people with purpose, leaders with systems, and teams with results.

Transformation isn’t easy but with a clear roadmap, shared vision, and sustained commitment, it is achievable.

Lean isn’t just about doing things better. It’s about doing better things and doing them together.

Subscribe and share your thoughts and experiences in the comments!

Professional Project Manager Templates are available here

Hashtags